Surface Mount PCB Assembly

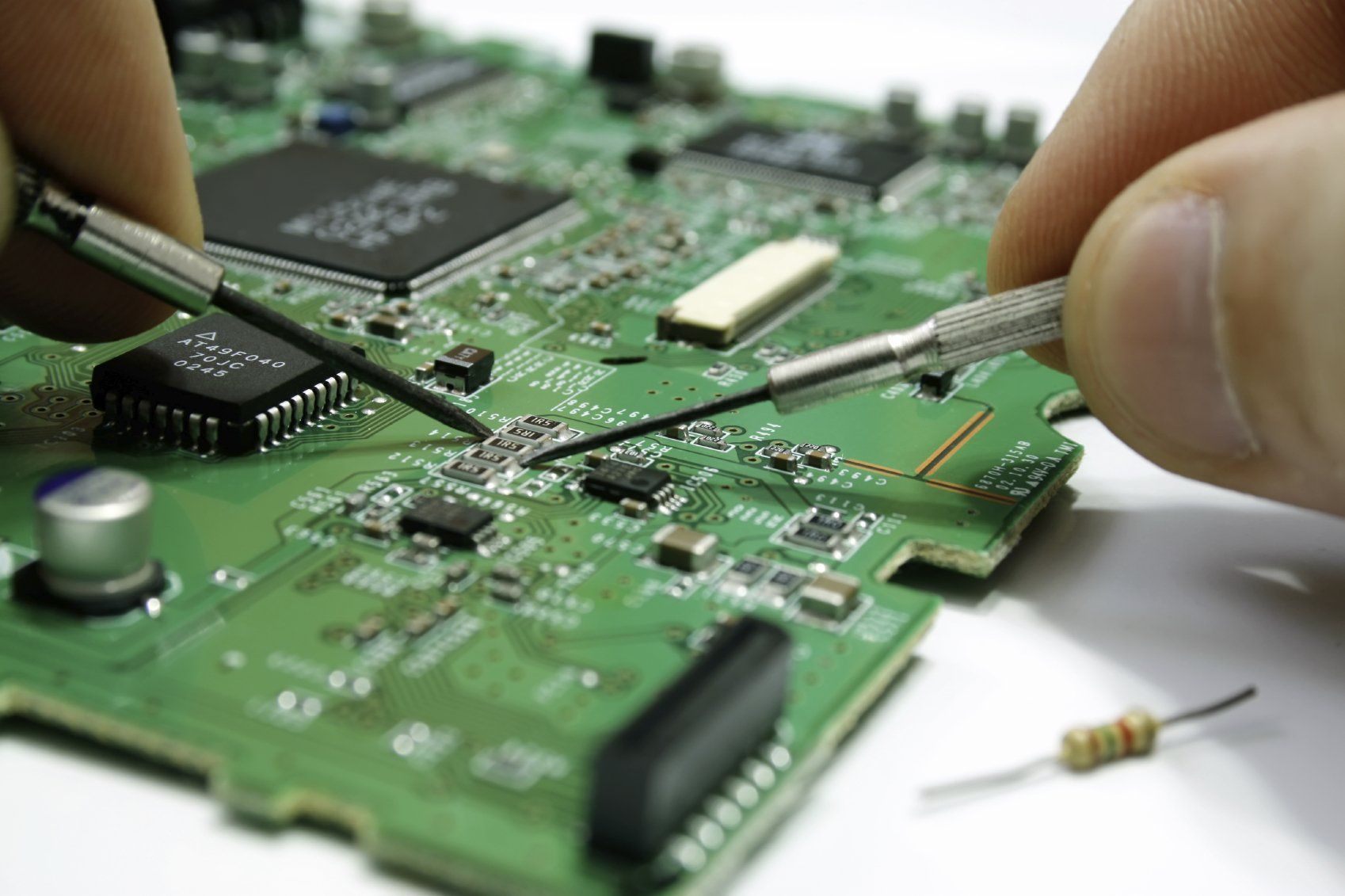

Chromatec Manufacturing has two SM lines, our main surface mount line is a Mydata MY Series, which can perform high-speed mounting of standard components at up to 21k per hour and fine-pitch placement at up to 10k. Additionally, we can place all types of components from 0201 through to micro BGA’s and QFPs, making it the perfect choice for flexible production.

All Silicon and PCBs are stored in a humidity control environment so they are ready to use immediately without the need to bake them to remove moisture.

Vopour Phase Technology

Chromatec Manufacturing recommend Vapour Phase technology, which offers customers a reliable, effective and safe soldering solution for high-density, complex boards. Vapour Phase affords much better control and stability over the entire soldering process, compared to traditional reflow soldering, regardless of board characteristics.

Vapour Phase reflow soldering is ideal for fine pitch components and BGAs as well as boards with large copper planes and traditional cold-spots, the vapour ensures a uniform temperature across the board without any hot or cold spots.

Complex high-density boards that would be a challenge for traditional infra-red reflow are easily profiled ensuring the highest possible yield.

For complex boards, Vapour Phase is fast becoming the only way to consistently achieve the highest production yields.