Turnkey-Solution

Chromatec Manufacturing is ideally suited for small businesses, start-ups and universities that want to bring low-to-mid quantities of assembled PCBs to the market, without the need for investing in their own SM line. We offer a complete solution, a cost-effective, efficient means of assembling and testing complete products.

Our turnkey solutions include electronics manufacturing services from designing, prototyping to assembly and testing.

CONCEPT

The objectives of the project are summarised and from this a document of the full specification of the projects technical scope is created. This is a crucial step as the specification is used throughout the entire project.

DEVELOPMENT PHASE

Our experienced engineers generate schematics of the design to meet the project specifications - taking into account factors such as ability to manufacture and purchasing of critical component selection. The schematic files and list of connections are sent to the CAD designer whilst the BOM is sent to the procurement team. This is a vital step to ensure the manufacture cost is kept low, and the longevity of the products components are taken into account.

In-house CAD designers work in conjunction with the design engineers to ensure that the layout meets the required performance.

If required, our in-house mechnical engineer can assist in designing the full box build of the product, producing 3D models of the product.

See more

about our design services.

PRE-PRODUCTION PHASE

This phase is critical to ensure the design and requirements of the project are assessed with client feedback. Further design revisions are produced, CAD layouts of the design is finalised, along with PCB fabrication and Bills of Materials (BOM).

MANUFACTURING & ASSEMBLY

Using the BOMs, and schematic design of the PCBs, the components are kitted, our pick and place machines are programmed and one of our skilled engineers will assemble the boards. Inspection quality is recorded at each stage of the manufacturing process to ensure reliability.

See more

about our PCB Assembly process.

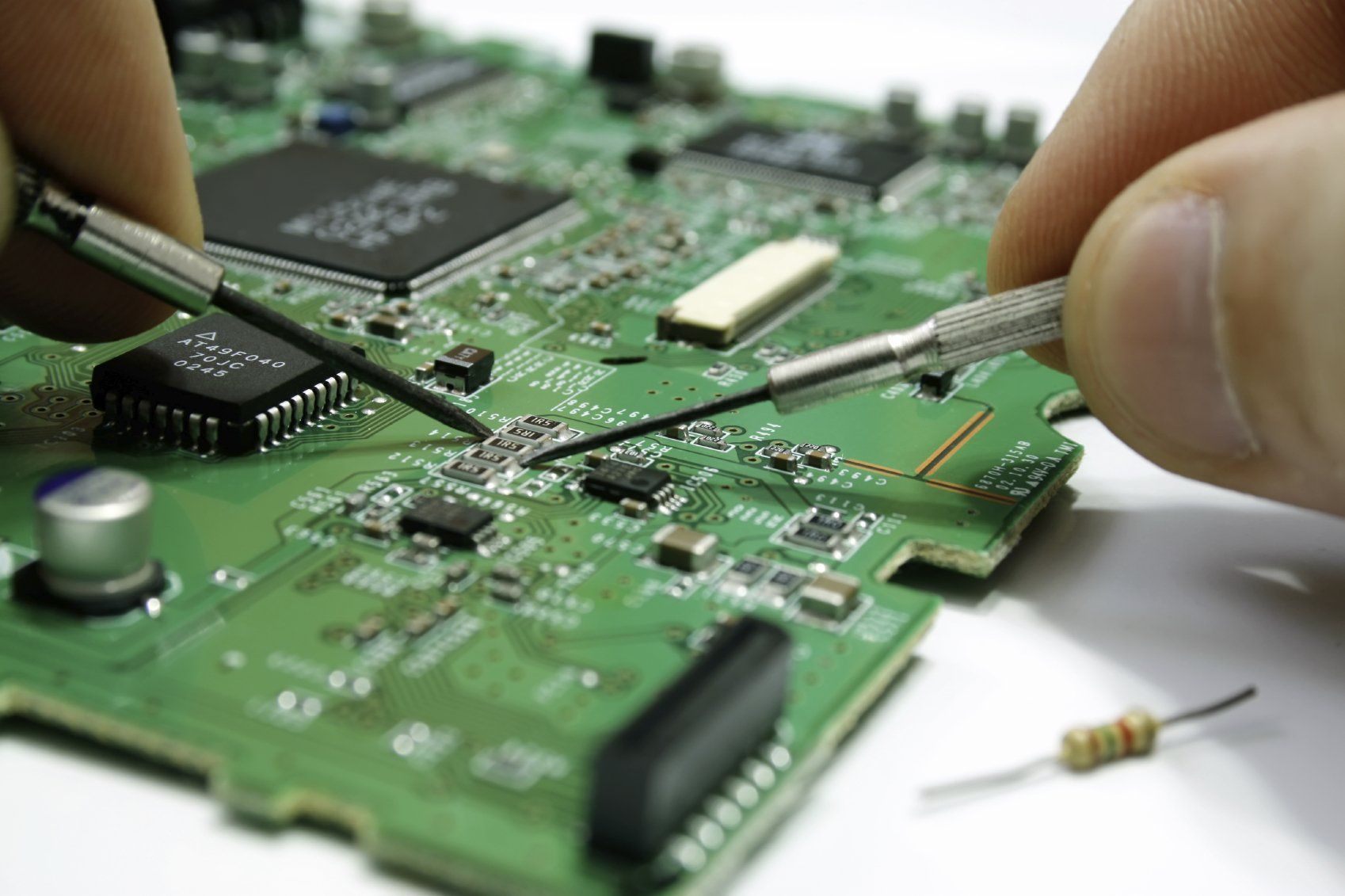

INSPECTION & TEST

We provide technical support to ensure the produced electronic PCB functions correctly and is reliable. We also have the capability to ensure firmware is programmed onto the PCB boards, and products are fully tested before shipment in a complete box build.

Contact us

Submit your request and we'll get back to you soon.